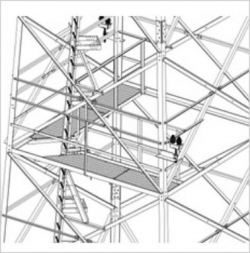

Self Support Towers

A Medium Duty, site assembled, knock-down, square self support tower. It suits applications for heights up to 90m.

Applications

- For microwave solid and grid antenna applications up to 4.60 meters (15’) diameter, depending on height and environmental loadings conditions.

- For GSM Cellular radio.

- For supporting UHF, VHF, YAGI and reflector type antennas.

- Various other antenna types and sizes, and loading conditions can be accommodated utilizing suitable sections of the tower. Check with LeBLANC Group Engineering Department for application.

Optional Items

The triangular series towers are supplied complete with legs, web members, base plates, ladders, rest platforms, anchorage steel as required. The following items are supplied as specified:

- Tower grounding

- Tower lighting (this may be either conventional red obstruction lights or strobe lights)

- Tower painting

- An interchange platform can be supplied at the top to facilitate access to a top mounted antenna

- A cable ladder to support transmission lines

- Antenna mounts to suit specified antennas

- Antennas and transmission lines are as specified by the customer

- Ladder safety climbing device and accessories

- Antenna ice guards

- Transmission line gantry

Features

- The Square series is a standard configuration

- The tower top face width is 1500 mm

- The legs are 90° angle members. Maximum leg length is 5800mm for ease of shipping

- The bracing members are bolted 90° angles. A ladder is mounted inside the tower for climbing

- Antenna mounts can be fitted to either the leg or face of the tower

- All structural members conform to ISO EN 10025 and JIS 3101 or equivalent Standards

- All welding conforms to the requirements of the AWS D1.1/D1.1 M:2008 AS/NZS 1554.1:2004 and Standards

- Towers are designed in accordance with TIA/EIA-222-G-2005, BS8100, SABS/SANS 10160, AS 1170-2, AS 3995, CSA S37-2001

- Standards or other applicable standards for the wind and ice loads specified for the particular site

- All material is hot-dipped galvanized after fabrication to ISO 1461, AS/NZS 4680 or ASTM A123 Standards

- All structural bolts conform to ASTM Standard A325 and galvanized to ASTM Standard A153.

- Manufacturing quality conforms to ISO 9001: 2001 Standard